Hastelloy Alloy is a kind of nickel based high temperature alloy.

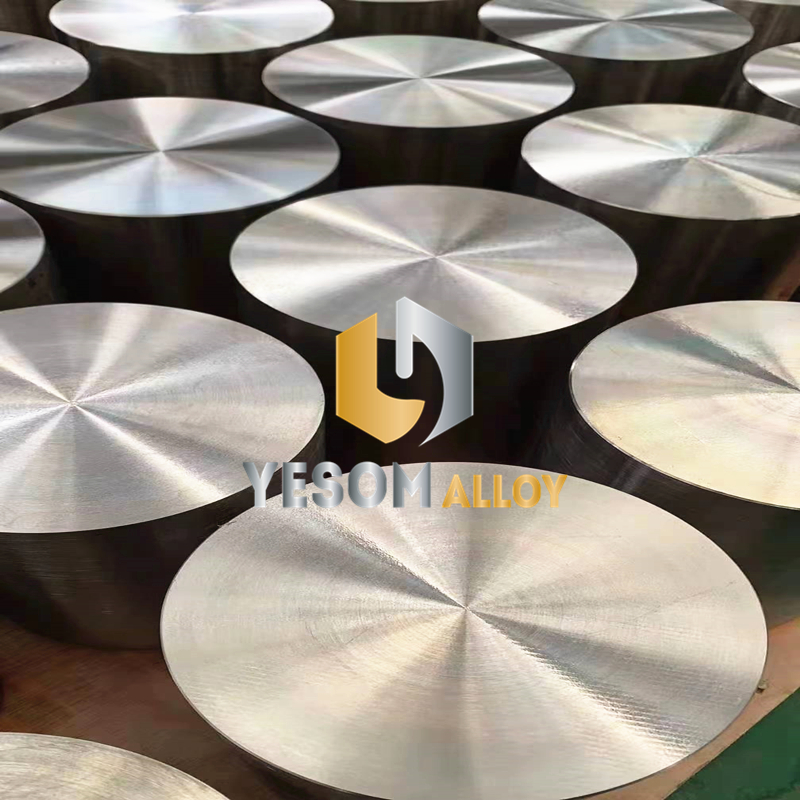

Yesom Group offers Hastelloy Alloy in shape of wire, bar, plate, strip, coil, flange, etc.

Alloy Grade: Hastelloy C-4 , Hastelloy C-22 , Hastelloy C-276 , Hastelloy C-2000 ,

Hastelloy B , Hastelloy B-2 , Hastelloy B-3 , Hastelloy X

Hastelloy C-4

| Hastelloy C-4 (UNS NO6455) | |||

| Chemical Composition % | Ni: Margin | Cr: 14-18 | Fe: ≤3.0 |

| Mo: 14-17 | Mn: ≤1 | Co: ≤2.0 | |

| Ti: ≤0.7 | C: ≤0.015 | Si: ≤0.08 | |

| P: ≤0.04 | S: ≤0.01 | ||

| Melting Point ℃ | 1335-1380 | ||

| Density g/cm3 | 8.6 | ||

| Application Area | Used for flue gas desulfurization systems, pickling and acid regeneration factories, acetic acid and agricultural chemical production, titanium dioxide production, electrolytic electroplating | ||

Designations: AWS 052

Specifications: ASTM B574 , ASTM B619

Alloy Details

Heat treatment of finished parts

Properties

Density

Melting Point

Coefficient of Expansion

Modulus of Rigidity

Modulus of Elasticity

8.64 g/cm³

1399 °C

10.8 μm/m °C (20 – 100 °C)

81.2 kN/mm²

212.4 kN/mm²

0.312 lb/in³

2550 °F

6.0 x 10-6 in/in °F (70 – 212 °F)

11777 ksi

30807 ksi

Condition as supplied by AWI

Type

Temperature

Time

Cooling

Annealed or Spring Temper

Stress Relieve

400 – 450 °C (750 – 840 °F)

2 Hr

Air

Annealed

Approx. tensile strength

<1100 N/mm²

<159 ksi

Approx. operating temperature depending on loading and environment

-200 to +400 °C

-330 to +750 °F

Spring Temper

Approx. tensile strength

1300 – 1700 N/mm²

189 – 247 ksi

Approx. operating temperature depending on loading and environment

-200 to +400 °C

-330 to +750 °F

The above information is typical. If you require different please ask.